Saving Money through Effective Procurement

Procurement is the process of procuring goods and services in an ethical and sustainable manor whilst satisfying the needs of the organisation. The Procurement Process is made up of a series of stages from Identifying the Requirement through to Contract Management. There are many perspectives on the stages, however the key stages can be summarised:

• Identifying the Requirement and Specification Development

• Sourcing the Market and Developing Contract Terms

• Selecting Supplier, Negotiation and Contract Agreement

• Contract Management

Those that buy within organisations varies from organisation to organisation. Depending on the business, procurement is undertaken by various departments and individuals from the most obvious Procurement Department, to Engineers, Production, Clinical Staff, Other Functional Heads, Office Managers, Stores right the way through to the Receptionist.

When I ask what do these buyers know about best practice procurement processes? The most popular response is “Nothing, but they have been doing it for years” or “our industry is different”. Ok, but doing the same thing for years does not necessarily mean its best practice or right; the world is changing, supply chains too. Organisations are under ever increasing pressure to save money whilst being ethical and sustainable. Is it possible? Quite simply, YES!

There are multiple ways of saving money, to get you started here are some tips just focussing on the procurement process

Identifying the Requirement and Specification Development

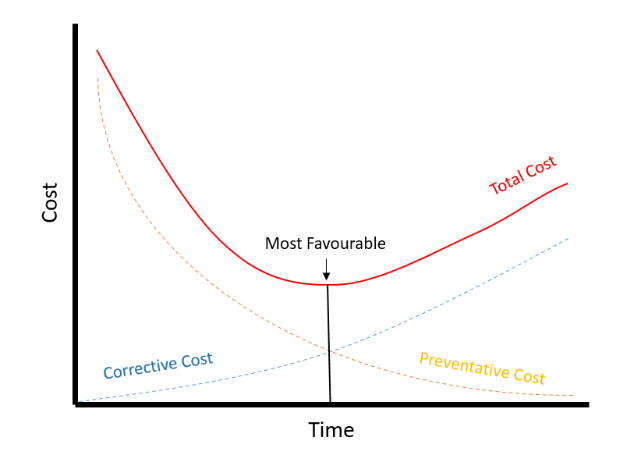

First ask yourself, do you really need it? Could it be repaired? Do you really need the same quantity and specification? Quite often, we replace items without thinking much about it, we have become a throwaway society. Think about introducing preventative maintenance, be careful though, you need to consider the balance between paying for preventative maintenance and that of corrective cost. As you can see from Fig. 1, move beyond the most favourable position and it’s no longer favourable once corrective costs start to increase.

Fig. 1 Balance between Corrective and Preventative Costs

Also, consider the quantity you purchase and the impact on inventory levels, you may get a great deal on bulk order price, but if you have to store it for long periods of time you must consider the stock holding costs; warehousing costs, handling costs, depreciation costs, obsolescence costs, security. It could just tip the savings scale!

Getting specification development right first time and standardising specifications can save organisations lots of money. Many organisations who are bleeding costs demonstrate this. Their specifications are developed by their technical experts or users without consultation with procurement or any other departments. This often leads to either over specified products and services, the use of brands, highly complex technical specifications resulting in the supplier trap. Built a product or service specification that can only be bought from one source, you guessed it, at a high price. More problems and costs arise when you would like to more from one supplier to another. Overcome these problems by insisting on the involvement of procurement who can balance those commercial and technical objectives; going beyond price and including the consideration of contract terms, payment terms, environment, social value and performance management. Quite simply, balance the objectives of the business.

Sourcing the Market and Developing Contract Terms

Consider the products and services you are buying and your sourcing options. There are a range of sourcing options such as sole, dual, single, multiple, international and partnering. They all bring their own benefits and drawbacks. Knowing which to choose can be difficult and will depend on your product or service. Buyers should always know their market and consider new options especially as markets change so fast. For instance, single sourcing could increase your negotiation leverage or improve supplier relationships, multiple sourcing could encourage competition and ideal for geographical reasons. International procurement could reduce your price, but be mindful of those total acquisition costs and increased supply chain risks. More and more we are seeing organisation partnering in their procurement, this has many added benefits including greater leverage. If you have been buying from the same supplier for years, best practice suggests that you should look at your sourcing options!

Consider the type of contract you use, Standard terms and conditions are ideal for your routine (low value/low risk) purchases, bespoke contracts may need to be developed for more important/high risk/high value products and services and don’t forget look at Model Form Contracts that could save time re-inventing the wheel and also reduce risk. Lots to explore here.

Selecting Supplier, Negotiation and Contract Agreement

Sometimes at this stage, buyers are hypnotised by the price when selecting suppliers, don’t be, use a balanced criteria, consider quality, reliability, safety etc too. This could save you money in the long run, a supplier that is reliable will save you many hours spent performance managing. Consider your corporate objectives, this will influence your decision on your criteria.

The best piece of advice I can offer anyone about to negotiate is to ignore the price list! They are there to condition you. Do your research, there is always room to negotiate, without going into lots of detail around negotiation tactics and techniques, there is always room to extract additional added value.

When you agree contract, don’t forget to include the finer details and of course get it signed. Read thoroughly before signing, ensure all the details are included, consult your legal team or ask if something doesn’t look right. Time spent at this stage is time well spent. Not only do contracts state the obligations of both parties they are there to reduce your risk and could save you lots in litigation.

Contract Management

Managing the performance of the contract is a stage which we often see ignored in businesses. If contractual performance is not being managed suppliers may become complacent resulting in poor performance which can have a negative effect on any savings or added value made during the procurement process.

These are just the tip of the iceberg, here at SR Strategic Sourcing our experts will listen to you, identify areas of weakness and together we will find a solution to the age-old opportunity of saving money. If your organisation would benefit from awareness of best practice procurement processes and the benefits they bring get in touch, we offer a wide range of courses, off the shelf and bespoke, suitable for operations, tactical and strategic levels of the business.

This article was written by Susan Rashid FCIPS, MBA, CPSM, PGCE, Founder & Managing Director of SR Supply Chain Consultants and Co Founder of SR Strategic Sourcing.

For further details and information on Saving money through effective Procurement and how this can help your organisation please contact us or click through to the following pages