Sustainable Procurement and Value Release in Food Processing

Sustainability, according to The World Commission on Environment and Development, is a process of change in which the exploitation of resources, the direction of investments, the orientation of technological development and institutional change are all in harmony and enhance both current and future potential to meet human needs and aspirations.

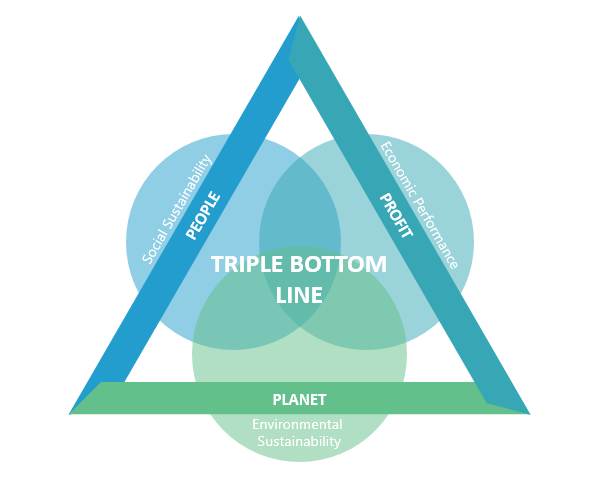

The three dimensions of sustainability became widely known in the 1990’s as the Triple Bottom Line (TBL), People, Profit, Planet.

The main body in the UK for developing environmental policy and drafting environmental legislation is the Department for Environment, Food and Rural Affairs (DEFRA), although the Department for Business, Energy & Industrial Strategy generally handles issues relating to climate change.

Sustainability is important to all organisations, not just because of legislation but also to protect our environment by ensuring resources are available for future generations and ensuring supply chains remain sustainable whilst ensuring they are economically sustainable too.

Procurement departments working in the food industry are faced with challenges such as Sustainable Food Production – using resources that do not exceed the capacity of the planet to replace them; the Environmental impact of food production and food waste. According to Defra, food and drink consumption is one of the highest contributors to environmental impact, however the largest impact occurs during food production and processing. Customer awareness is increasing, and consumers are demanding action. Organisations can no longer hide and must step up and take action.

The 2030 Agenda for Sustainable Development is a global agreement designed to eradicate poverty, inequality and injustice which succeeds the Millennium Development Goals. The UK have been at the forefront of negotiating and delivering these goals. The 17 Sustainability Development Goals include:

The UK have also published a Voluntary National Review, reporting its progress so far against these goals. Organisations from all industries can support these goals by creating strategies and implementing policies to tackle waste, resources and the use of plastic, reducing waste, tackle waste crime and improve energy efficiency.

Buyers can contribute to the triple bottom line by sourcing sustainable products ensuring that they include consideration of people, profit and planet. This can start begin at challenging the need, developing the specification to include sustainable resources, environmental measures such as ensuring resources and materials that are sustainable, utilising processes that use energy efficiently or the use of renewable energy, minimising waste and pollution whilst ensuring the suppliers are paid a fair price.

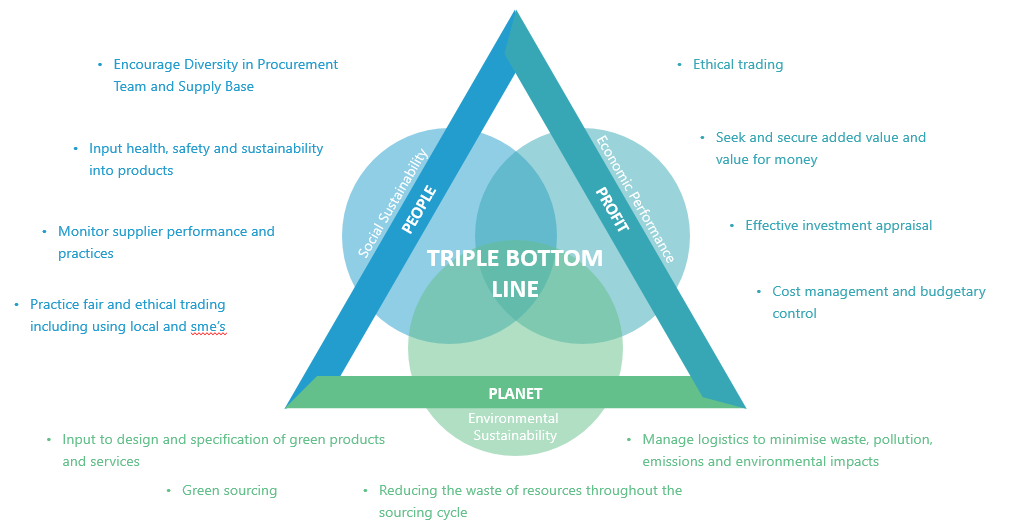

There are many contributions procurement departments in the food processing industry can make which can be seen in the diagram below;

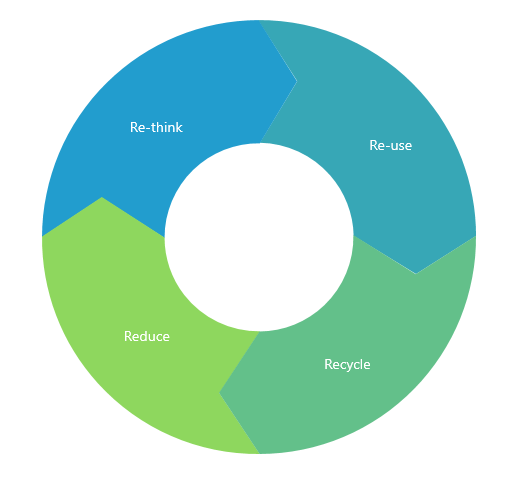

On a more practical note, procurement in the food processing industry can promote sustainability by considering the 4 R’s of procurement; reducing the amount used, re-thinking whether it is actually a genuine requirement, re-using existing or ensuring products can be recycled. This should be used throughout the procurement cycle but has significant impact when “challenging the need”. Personally, I like to add a 5th “R” – “Repair”!

Buyers in the food processing industry should consider the use of packaging and plastics; do they need it? Can it be reduced? Can it be recycled? Can carbon footprint be reduced by buying local with the added advantage of reducing lead times? Closed loop supply chains?

Many would think it is as simple as “stop using plastic”. Interestingly it’s not, Marks and Spencer’s work on food packaging demonstrated that packaged apples create no more impact on the environment than loose unpackaged alternatives; and paper carrier bags have twice the environmental impact of polythene alternatives (Defra).

Many organisations have chosen to join the UK Plastic Pact which is a collaborative initiative with targets to deliver by 2025 that include;

- 100% of plastic packaging to be reusable or compostable

- 70% of plastic packaging effectively recycled or composted

- Eliminate single-use plastic packaging

- 30% average recycled content across all plastic packaging

Buyers should ask themselves whether products in a specification have become unsustainable? It is surprising how many organisations have been sourcing a product year on year and have not considered whether it is unsustainable until their supplier hits them with a hefty price increase. Monitoring this on a regular basis is essential for buyers to mitigate not just environmental risk but supply risk to.

From an environmental perspective, buyers should consider their supply chains and what they are doing to reduce water consumption, waste, energy usage and not forgetting food transportation.

For the social aspect, buyers must monitor their supply chains to ensure ethical trading, health and safety, equal opportunities. Organisations can start but ensuring suppliers are paid a fair price with sustainable payment terms to encourage the sustainable development of their supply chains.

The benefits for organisations that can be achieved through positive action on sustainability can include:

- Competitive Advantage

- Compliance to legislation

- Reduced costs

- Sustainable Goals

- Increased efficiencies

- Improved image and reputation

- More attractive to customers

- Reduce Risk

After a Sustainability Policy has been developed and commitment obtained Procurement should start at the beginning of the procurement cycle and consider people, profit and planet at each stage which will includes challenging the need, developing the specification, sourcing the market, supplier appraisal, supplier selection, developing and managing contracts, supplier performance, vendor rating and payment.

Helpful links & references

This article was written by Susan Rashid FCIPS, MBA, CPSM, PGCE, Founder & Managing Director of SR Supply Chain Consultants and Co Founder of SR Strategic Sourcing.

For further details and information on Saving money through effective Procurement and how this can help your organisation please contact us or click through to the following pages