Bottom Line Savings through Procurement - Part 3 of 3

"Stage 2 - SPM, SRM and Contract Management"

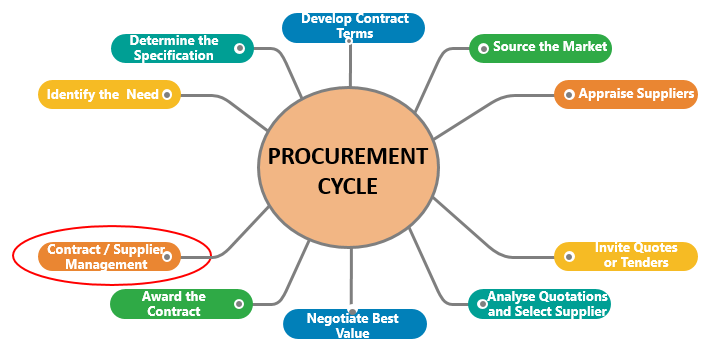

In the previous article we discussed how Procurement delivers bottom line impact through the Sourcing stages of the Procurement Cycle.

In this article we move on to the final stage of the Procurement Cycle, Stage 10, Contract and Supplier Management. Do we drift into the end, has all the hard work been done and is this just the wrap up to finish the cycle off? NO, if we do not undertake this area seriously and appropriately with sufficient resources, then we will lose all of the value that we have created so far.

Please see the diagram below, which we have used throughout this series of articles, where Contract / Supplier Management represents Stage 10 only.

Does this mean it only represents 10% in terms of its value to the cycle as it looks visually? NO, this is as significant an area as the other two phases and easily justifies at least 33% of all value achieved. This misconception has cost Public and Private sector Organisations £Millions and is still costing those who are not embracing Supplier Performance Management, (SPM) and Supplier Relationship Management, (SRM) please let me illustrate below:

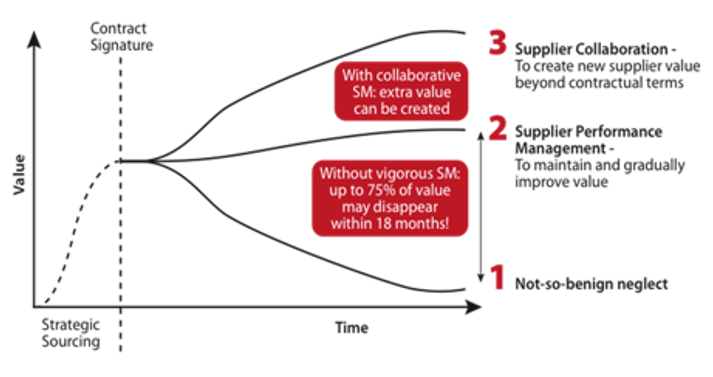

From the point of contract signature statistics and analysis suggest that, if a contract is not managed effectively, Suppliers will quickly recognise this and the buying Organisation will lose up to 75% of the contracts added value over an 18 month period. Why? because they can! Who will a Supplier perform for – the customer who manages them diligently through SLA’s, KPI’s frequent review meetings with minutes and actions etc., or the customer who doesn’t manage them at all? Not a difficult one is it?

In my view, the issue here is industry / sector specific. In the automotive industry, I was involved in the development of a Supplier Performance Improvement programme and the successful creation and delivery of a robust Vendor Rating System. My Organisation, a first tier automotive Supplier, had the benefit of being Supplier managed by companies such as BMW, Jaguar, Land Rover etc., where effective Supplier performance measurement and management was embedded through the tiers and accepted. In many other Private Sector industries, this is still not the case and huge value is lost daily.

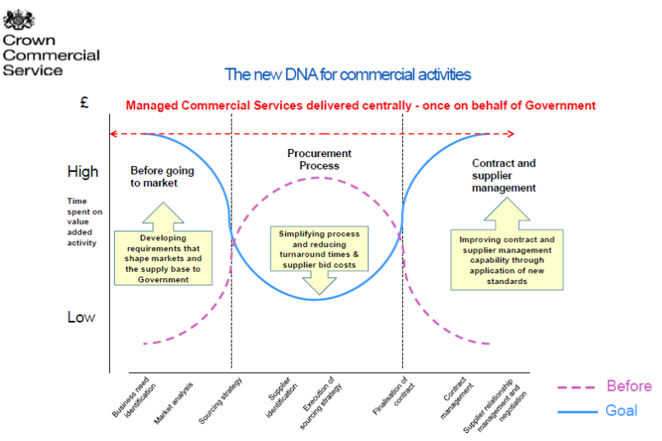

Until quite recently this was definitely an area that was neglected in the Public Sector and was an opportunity for exploitation for Suppliers. This is the Public Sector, where up until Stage 10, the Procurement Cycle was delivered flawlessly delivering a competitive commercial result with full traceability and transparency throughout. In recent times the Public Sector has definitely started to recognise and rectify this issue, please see the extract below from Crown Commercial Services demonstrating this:

The lilac line depicts the comments above and the old perception and the blue line the goal, with the recognition of both the Pre-Sourcing Stage, see Article 1 of this series, and the Contract / Supplier Management Stage, which is great to see.

Diligent Supplier Performance Management will ensure that the Supplier delivers what you expect from them. Activities such as review meetings, covering SLA’s, KPI’s, Minutes, Actions and maybe a Vendor Rating System will drive the Supplier to continually improve their performance. These activities will also quickly identify any under lying issues relating to areas such as quality or delivery on time, capacity etc. Complemented by areas such as Root Cause Analysis, followed up by effective Corrective Action, will provide a Supplier Manager the information required to make quality managerial decisions, relating to further Supplier development or a cause for concern to be shared with the Procurement / Category Lead for the product or service.

Consistent Supplier Performance, hitting all measures, to some extent should be a given, what else can they offer me? From your Supply Positioning and Supplier Preferencing Analysis, a strategic procurement employee will know the areas in their category that matter, in our world the top right hand corner of the Kraljic Matrix, which is the initial area where we should be undertaking Supplier Relationship Management, (SRM).

All Organisations have limited resources and cannot engage in SRM with every Supplier, but for the ones identified in the previous paragraph, this is imperative.

Increasingly, in the modern environment, our Supply Chain will deliver our Competitive Advantage. What we do together with our key and Core Supply partners, for mutual benefit, will make the difference for our Organisations. That new innovation that we have worked with our Suppliers on through New Product Development, (NPD). That new product that our Supplier has that we have secured exclusivity for.

With our Core Suppliers that are critical to our Organisations, it is crucial that we are seen as a ‘Customer of Choice.’ It needs to be our Organisation that works with them on NPD and Innovation. If you see one of your Core Suppliers new products being featured by a competitor of yours and you are not aware of it, then your relationship is not in the right place.

With a select Core of Critical Supply Partners, through effective SRM, we can achieve things that may be transformational for our Organisations, this is the significance of best practice SRM. ‘It is not essential, we need to spend our budget and resources elsewhere’ I hear. You can’t afford not to do it!

To undertake effective SPM and SRM, you need the following:

Resource the function adequately and the payback will be significant and measurable over a relatively short period of time, through a suite of appropriate SMART KPI’s, quantifiable, tangible, bottom line benefits!

This concludes our series of articles relating to the Procurement Cycle. If you would like to discuss your current Sourcing Process, or how you currently undertake any element of the Procurement Cycle further and how it may be improved or optimised, please contact us and we be delighted to help you.

This article was written by Gary Tinsley FCIPS, BA (Hons), DTLLS, Co Founder of SR Strategic Sourcing Ltd.

For further details and information on Managing your Supplier base and how this can help your organisation please contact us or click through to the following pages

Adding Value though Effective Contract Management in the Public Sector

Generating Social Value from Effective Procurement

Commercial Awareness for the Supply Chain and Procurement team