Bottom line savings achieved through Procurement

Article 1 of 3 - Stage 1 - Pre Sourcing

There are people who still don’t get it – what is Procurement? what does it do? Anybody can buy things, why do you need a department for this? Surely we could save that money and resource and use it better elsewhere?

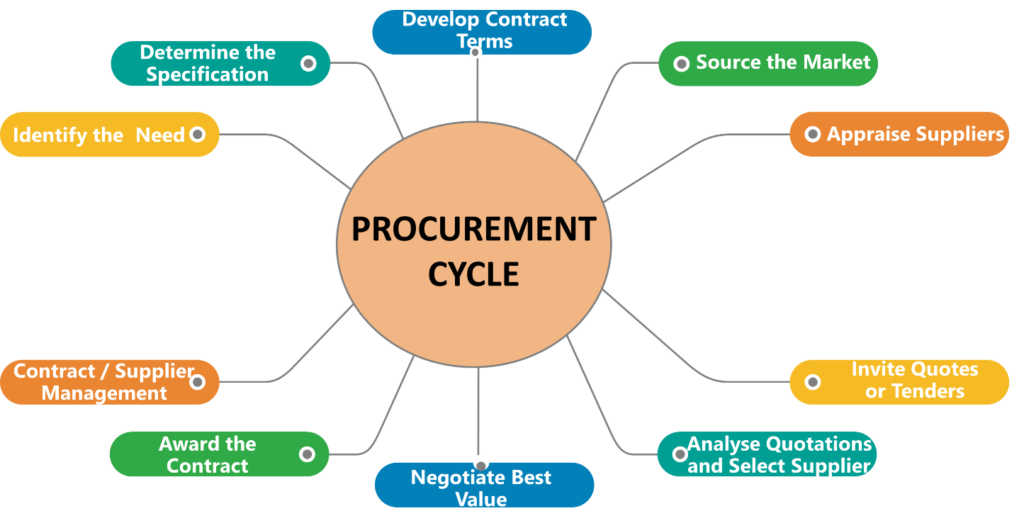

Procurement adds significant value at every stage of the Procurement Cycle, generating savings and very often, more importantly, avoiding unnecessary costs and mitigating all types of risk. In this series of articles, we will refer to the following version of the Procurement Cycle, which in our opinion is still the best.

Originally, I set out to write this as one article but I am sure you are delighted to hear, I could not do it justice in one sitting. This first offer, will concentrate on Pre-Sourcing activity, an area were many stakeholders will consider that we do not add any value at all, they couldn’t be more wrong, this actually is arguably the area of the Procurement Cycle were we add the most value!

1. Identifying the Need

At this stage Procurement must ‘Challenge the Need’, does the user actually need it? Do we already have it in stock under a different code?

Do we have a standard item, again ideally in stock, that can do the same job? Do we have an excess stock item that could fulfil this role? Can we utilise the 4 R’s, the responsible, sustainable method of not making a procurement at all.

At the end of the day, ‘the best saving you will ever make is not buying the product / service at all’

Many banks and financial organisations use ‘Gateways’ and the first Gateway is for a committee to Challenge the Need with a mindset of the answer is No unless you can fully justify the requirement. This is a fantastic deterrent and leads to significant savings being achieved, evidenced by a review of year on year spend in similar areas and categories.

2. Determine the Specification

This area is probably the one single area where the most influence and significant savings can be made. This area warrants a full article in itself which I will probably go on to do at some point. Here Procurement can add huge value and gain significant credibility with internal Stakeholders. The following are just some areas when Procurement can add value in Specification Development:

- Variety Reduction, Reduction of Stock Proliferation and Procurement Product Awareness

We need to reduce the variety of similar things and take the pressure off our friends in the Warehouse and Operations of the business. Every item stocked, needs to be ordered, booked in, located, moved around and paid for. There is a well-known statistic that suggests for every year that a product is sat on a shelf in a warehouse it costs at least 20% of its original cost, plus the risk of obsolescence, deterioration, perishability etc. Procurement should be the custodian of the SKU count and cap it at an acceptable agreed level.

Internal Stakeholders will specify what they want, at that time, with no other consideration as the product / service may be a minimal contributor to their overall project. Procurement professionals, especially if organised by category, will have great product awareness and may identify a product from existing stock that can fulfil the stakeholders need. This little contribution adds huge value to the Organisation, preventing any purchase being made and reducing excess stock levels.

- 2. Standardisation

Just a few fundamental basics to add here from buying a standard against a special:

o Standards are easy to buy – Conformance Specification

o The quality is consistent – to standard

o The price is more competitive as there will be many manufacturers who can supply to standard

o The global market is available, any supplier who is aware of it and can meet the standard is potentially viable for supply, e.g. DIN, EN, ISO etc.

o Standards have no / lower Minimum Order Quantities, (MOQ’s)

o Standards are available, in stock, or on a very short lead time

o You can always sell a standard, it is unlikely to become a stock problem.

Special / bespoke products are basically the opposite, e.g. high MOQ’s, long lead-times, much more expensive, one use only, potentially a stock problem, unique to you and the Supplier only, to the Supplier’s specification – TO BE AVOIDED!

- 3. Performance not Conformance

Converting a Conformance Specification to a Performance Specification will open up the Supply Base that we can utilise. Very often a Conformance Specification will be a preferred Brand from the stakeholder, e.g. for a laptop. If we can convert this brand to a generic specification there is a strong chance we can make savings and provide benefits for our stakeholders, i.e. an equivalent laptop for a lower budget or a much higher specified laptop for the same budget. Converting Conformance to Performance, allows us to enjoy and benefit from the expertise and market awareness of our Suppliers away from any restrictions.

- 4. Early Supplier Involvement (ESI)

The supplier is the expert in the product / service that they manufacture, distribute, deliver, we are usually not, despite what our stakeholders may think!

Therefore, we should use / engage our Suppliers when determining a specification. This is a key area for gaining internal stakeholder credibility. Our stakeholder may only have an idea of what they want. Why not invite in three Supplier specialists from the related area and ask them to present what is available in the market place and their recommendation. From this rich, primary data, procurement and its stakeholder can determine what they actually need, which may be a combination of some elements of each of the supplier offerings. Be wary that each Supplier may try to steer your requirements to something only they can supply. This is easily avoidable and the benefits of ESI far outweigh any risk.

With engagement, a Supplier expert can advise you quickly if an idea that you may have is viable, this will save you a great deal of time and resource. Your Suppliers can advise you on design, materials, manufacturing methods and many other areas adding significant value in many ways.

In the next article in this series Bottom Line Savings Part 2 we will move on to discuss how Procurement delivers bottom line benefits during the Sourcing Process.

This article was written by Gary Tinsley FCIPS, BA (Hons), DTLLS, Co Founder of SR Strategic Sourcing Ltd.

For further details and information on Managing your Supplier base and how this can help your organisation please contact us or click through to the following pages

Commercial Awareness for the Supply Chain and Procurement team

Adding Value though Effective Contract Management in the Public Sector