Minimising Supply Chain Vulnerability

Through effective Procurement training

There’s no doubt that in this age of Industry 4.0, Procurement and Supply Chain are the owners of Supply Chain Risk.

For the first time ever Procurement is now making the national news and Procurement people are now being interviewed on TV. “Why“? you may ask. Because there is a desperate need for PPE, Ventilators etc. in the NHS and the ownership and responsibility to deliver very firmly lies with Procurement. Nobody in a Procurement role is responsible for the cause of the Coronavirus Pandemic, however it is our job to solve the supply issue and our profile has never been higher.

So how can we help Procurement and Supply Professionals to manage and mitigate any vulnerability in our supply chains?

Risk Identification

As a Procurement and Supply Chain Professional we can not let risk events happen to us and say, ‘It’s not my fault, how could I have known’, it is our job to be Proactive and Aware. Our level of market knowledge and awareness for our product / service areas should be greater than anybody else’s in our Organisation! Our supply chain(s) should be solid and secure to protect our organisations and our customers.

Here’s a number of things we can do to identify risk and vulnerability which will enable us to increase our awareness and protect our Organisations:

• Fully understand our MACRO External Environment to gain awareness, undertake a STEEPLE exercise. This will inform you of the bigger picture occurrences that we can not control, e.g. Brexit. Don’t let these things happen to you, be aware and proactive and create a solution as early as possible.

• Analyse our MICRO External Environment. We need to be aware always of what is happening in our Industry; is there a new Supplier or new products in the market place? Is there a completely different way of doing things and do we have access to it?

• Protect our key lines – what are our Pareto items, what are the 5% of our products that are on every customer order? If they are sourced globally, do we have a domestic back-up? Do we have a plan for the C Class product which is low spend / value but there is one for example on every vehicle?

• Undertake a Process Mapping exercise to identify that one area of vulnerability, the item that has one supplier, e.g. a particular micro chip in a mobile phone and fix it, source a back-up supplier back-up product.

• Is your supply chain fully traceable back to the raw materials? Does your industry require this? If so, we need to ensure this robustness in our supply chains. It only takes one product sourced from a Supplier practicing Modern Day Slavery and your brand / reputation could be irreconcilably damaged, there are many examples of this and I am sure you know who they are.

• Has it happened before? Review your incidents of supplier / product failure and Corrective Actions to close out and ensure that repetition can not occur.

• Engage with all affected stakeholders and flipchart every last possible risk that you can think of, then assess these risks.

Risk Assesment

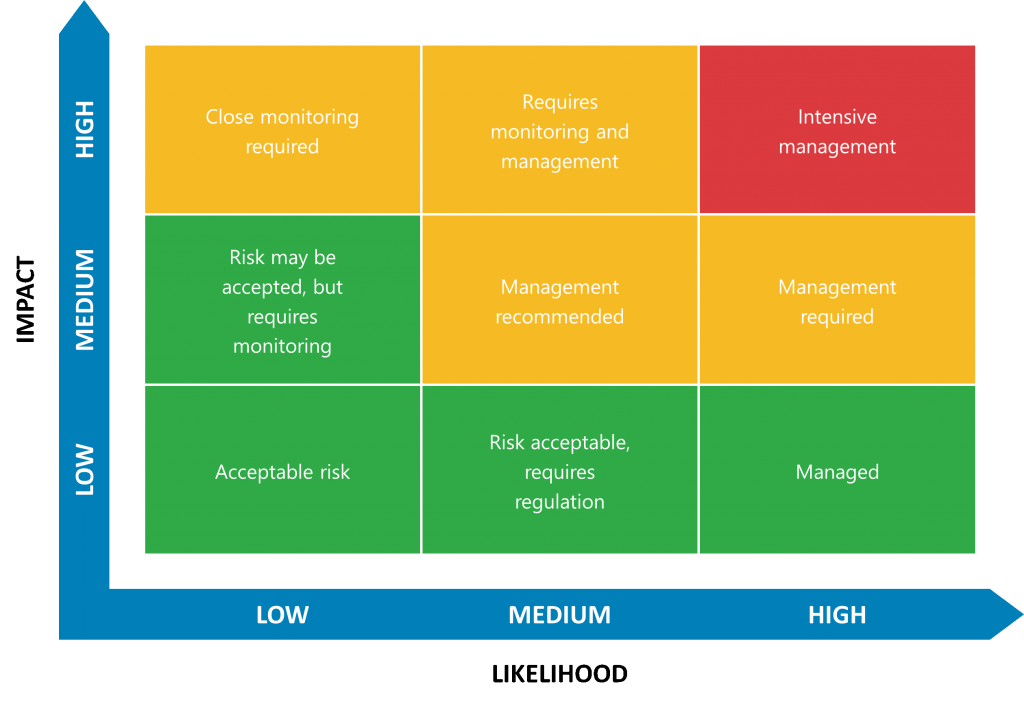

Take each and every risk that you have identified and score it accordingly. Risk is and assessment of Likelihood and Impact, some risks are more important than others.

This exercise, especially if your score the 2 axis from 0 to 5, 0 to 10 etc. will enable you to score risks and sort them in descending value order to determine areas for immediate action and other risks that essentially you can tolerate.

Risk Management

From the list created in Risk Assessment, we then need to allocate ownership, actions and timescales. This will form the basis of a Risk Register which is effectively the risk management control document. This is simple but good practice and will enable us to mange our risks out and protect our Categories and Organisation.

Review Controls

Continuous improvement through evaluation and review is crucial to success. You must constantly challenge the process to pursue small incremental steps of improvement to aim to eliminate risk and improve performance.

Risk Cycle

By simply following the Risk Cycle, see below, thoroughly and comprehensively you can potentially prevent, manage and mitigate the majority of risks.

The key to success is diligent, effective Risk Identification. Be creative, work with Suppliers / Colleagues and fully understand your market place and have access to current industry news / updates.

In today’s world organisations are competing through the effectiveness of their supply chains. The strongest, most agile and flexible but robust supply chains will be the ones that prevail and succeed.

This article was written by Gary Tinsley FCIPS, BA (Hons), DTLLS, Co Founder of SR Strategic Sourcing Ltd.

For further details and information on Managing your Supplier base and how this can help your organisation please contact us or click through to the following pages

Managing and Mitigating Risk in your Supply Chain