So how does Procurement help and contribute to improved Inventory Management?

Let me start with an anecdote…. I once went for the role of Procurement and Inventory Director in a £200 Million mail order retail business with 20,000 Stock Keeping Units (SKU’s) and a team of 15 Stock Controllers. At the interview I stated that I had never been responsible for an Inventory Management function or any Inventory Management staff, which you would expect would lose me the role.

What I also stated was that I had worked in Procurement and Supply Chain for over 12 years and was more than aware as to how Procurement affects Inventory Management. In fact Inventory Management / Stock Control are the recipient of the arrangements made by Procurement people / Buyers with their Suppliers, i.e. if the Procurement people haven’t given Inventory Management a second thought, then this places the Stock Controller in a very poor initial position from which it is now difficult to negotiate any improvements to agreed terms.

In the interview I went on to discuss the following aspects of how Procurement can help Inventory Management /Stock Control and got the job!

'Small Quantities Often’

As per the first article in this series, ‘Cash is King’ and Procurement have a level of ownership for keeping the cash flowing. We can have a huge impact on working capital and delight the Finance team!

One simple method is to reduce lead times. If we can reduce a lead time for example from 8 weeks to 4 weeks or 4 weeks to 2 weeks this will have tremendous effect in many ways. We can order and receive more frequently and most importantly carry less stock and improve the space utilisation in our operation / warehouse. This will impact the stock value and stock turn very positively and is something to challenge / work with Suppliers on constantly. If you can provide them with a better vision / forecast to allow them to optimise their manufacturing, then in return they will support your needs, even carry stock for you to enable you to minimise, even eliminate, your lead times. This will have a huge cashflow impact for your organisation.

‘Stock Proliferation and Variety Reduction’

From earlier, having ‘got the job’, I inherited a huge amount of excess stock and 20,000 SKU’s in a mail order Buying environment. The SKU’s were categorised / stratified well but for simplicity in this article, let’s use Categories, A, B, C and D, sorted by usage / value, a development of classic Pareto theory.

Within this was a range of water based paint, used for primary children to paint in class. We had in excess of 400 SKU’s for water based paint, bottles of various colours, sizes and bottle cap variation from many suppliers, even duplication of bottles but from different suppliers.

I tasked the team with reducing the SKU count from over 400 to 40 variations of paint bottle, to the exasperation of the Art and Craft buyers. We needed to select one cap type, a smaller range of colours and a standardised, reduced range of bottle / capacity sizes. We didn’t quite hit 40 varieties of paint but we were relatively near, with a negligible effect on sales. What benefits did this bring?

- A rationalised supply base

- Less orders and invoices

- The clearance of over 300 warehouse locations

- A vast creation of warehouse space

- A significantly reduced level of stockholding

We moved to a small number of frequently moving lines, all based on short lead times, with the Suppliers delivering a huge value of Total Cost of Ownership savings.

This exercise was complemented by a strategy of one in, one out when adding additional SKU’s. If a Buyer was looking to add a SKU, they would also have to nominate a SKU to be removed from their portfolio to maintain the SKU count and prevent stock proliferation.

‘SKU Rationalisation and Optimisation’

In addition to the previous strategies to improve cashflow, a strategy was undertaken to reduce the SKU count from 20,000 to 16,000, by a blanket discontinuation of 4,000 ‘D’ line’s. D lines were minimal selling lines and the removal of 4,000 products would generate huge operational and warehouse benefits for the organisation to the extent where on the back of this strategy, the need for external warehousing was eliminated, generating very significant operational savings for the organisation and major cash benefits.

Additionally, relating to D lines a strategy was put in place to only order these items following receipt of a customer order and to not accept any MOQ’s. If we were unable to reduce an MOQ then the customer would have to order the MOQ, again minimising stock quantities and value of these items – benefitting cashflow.

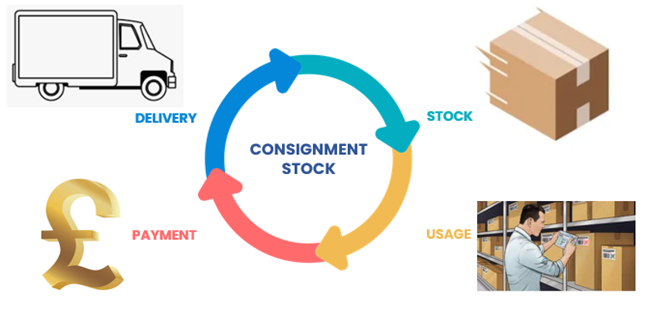

‘Consignment Stock and Vendor Managed Inventory (VMI)

Consignment Stock is effectively the Supplier’s stock, held on your site and you only pay for the stock that is used, when you use it and it is the responsibility of the Supplier to replenish this stock to the agreed levels per line on an agreed frequency. This effectively eliminates the need for you to hold any stock and any lead time, delivering major cashflow benefits. Procurement should be able to negotiate this arrangement with key strategic partners.

Vendor Managed Inventory, (VMI), takes this a stage further. In this instance the supplier holds the stock for the buyer on their site. The Buyer is able to call-off this stock on a same day / next day basis and the Supplier then supplies. This again generates significant cashflow and space optimisation benefits.

‘SKU Reduction Programme’

Stock ties up your cash, especially excess long stocks. The longer the stock is held, the less chance of liquidating it. SKU’s should be categorised by age, e.g. > 6 months old, > 12 months old, > over 24 months old. The concentration of effort should be at all levels but especially on the stock held for more than 2 years. These areas need a strategy to move the stock by any effective way, e.g. –

- Discount it to sell it

- Create Special Offers, maybe even give stock away as part of an offer

- Offer the stock to a clearance specialist, (less preferred)

- Ultimately, if needed, scrap it. This is the least preferred option as stock will need to be written off, however it will result in a true stock figure, as against a falsely inflated value

For any stock in the > 6 months category, the parameters should be reviewed and improved, e.g. lead times, MOQ’s, MOV’s.

‘Minimum Order Quantities’, (MOQ’s) and ‘Minimum Order Values’, (MOV’s)

Procurement staff should aim to eliminate MOQ’s as much as possible. If you have an annual volume of 2,000 pieces, a MOQ of 1,000 pieces reflects 6 months stock, this is unacceptable. In a previous role, I inherited Wellington Boots, ‘Wellies’ as a stock line. To my shock, I was advised that we had over 150 pairs of extremely slow moving, size 14 Wellies in stock and no size 10’s! During a discussion, it was determined that the MOQ for Wellies was 200 pairs for all sizes. This is ok for sizes 6-10, where the majority of the volume is but not ok for size 14 wellies! This reflects poor Procurement. The correct solution here would be to buy size 14 wellies as and when they are ordered by a customer by the pair, on a short lead time from a selected supplier. If this costs more for the individual pair, then a minor price increase for 1 pair will be the correct Total Cost of Ownership decision and the best result from an inventory management and cashflow perspective.

Similarly Procurement staff should look to also eliminate / negotiate away any MOV’s as again this could be detrimental to effective inventory management.

Hopefully from this article, you have picked up some valuable tips with regards to things Procurement can do to benefit Inventory Management.

This article was written by Gary Tinsley FCIPS, BA (Hons), DTLLS, Co Founder of SR Strategic Sourcing Ltd.

For further details and information on Managing your Supplier base and how this can help your organisation please contact us or click through to the following pages

Adding Value though Effective Contract Management in the Public Sector